It is a matter of translating the item and/or sample available to the customer into lines and machining instructions. Often the end customer only has a vague idea of what the product they are going to place on the market might be, without even having asked themselves what type of material to use, or the quantity of parts the equipment will have to produce.

The designer’s task will therefore be to first identify the best equipment, in relation to its costs, benefits and durability. To do this, it will be necessary to hypothesise: the number of cavities depending on the quantity of the minimum batches envisaged, the raw material to be processed (aluminium, hardened and tempered steel, stainless steel) the thicknesses of the surfaces (to reduce weight and therefore the final moulding cost) and the finish.

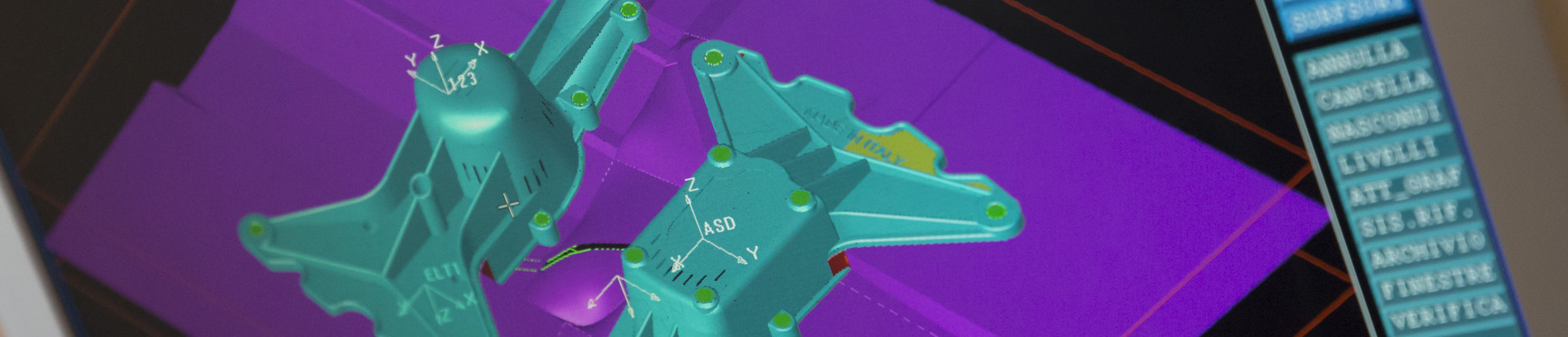

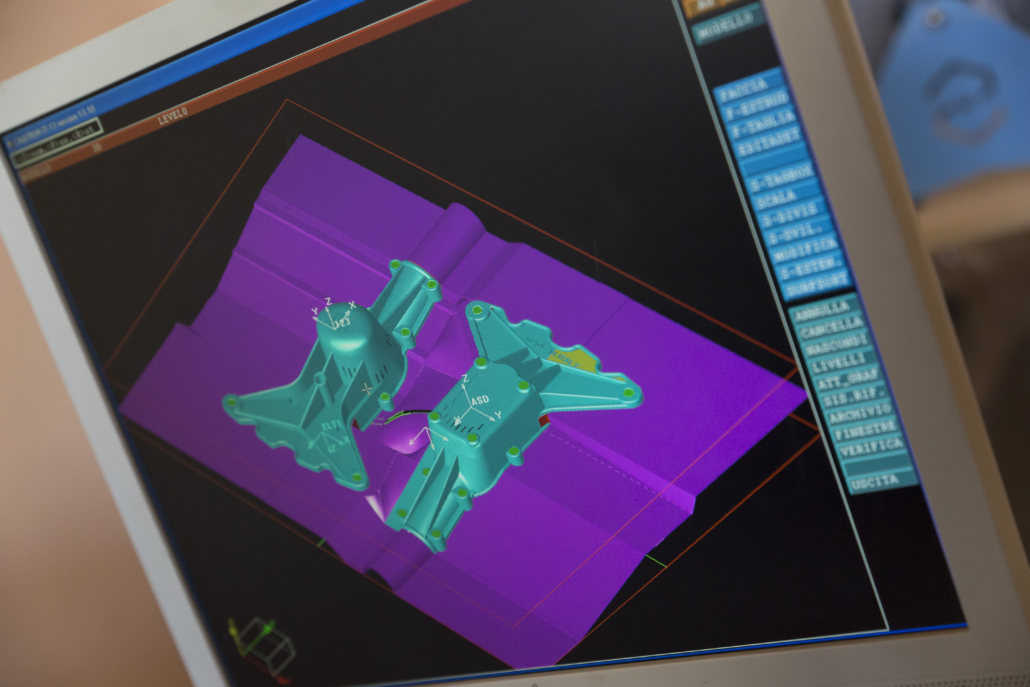

A service of great interest is the possibility of making rapid prototypes by means of three-dimensional surface detection to verify the operation and functionality of the designed article, according to the customer’s requirements.

SAMP Stampi e Stampaggio S.r.l.

Via Bramante, 6

50028 Barberino Tavarnelle Val Di Pesa (FI)